From the CTO’s desk

Gomatam Ravi

The last few months have been busy on the research and development front, and I’m happy to share the following important updates that mark a big step forward for GPS Renewables:

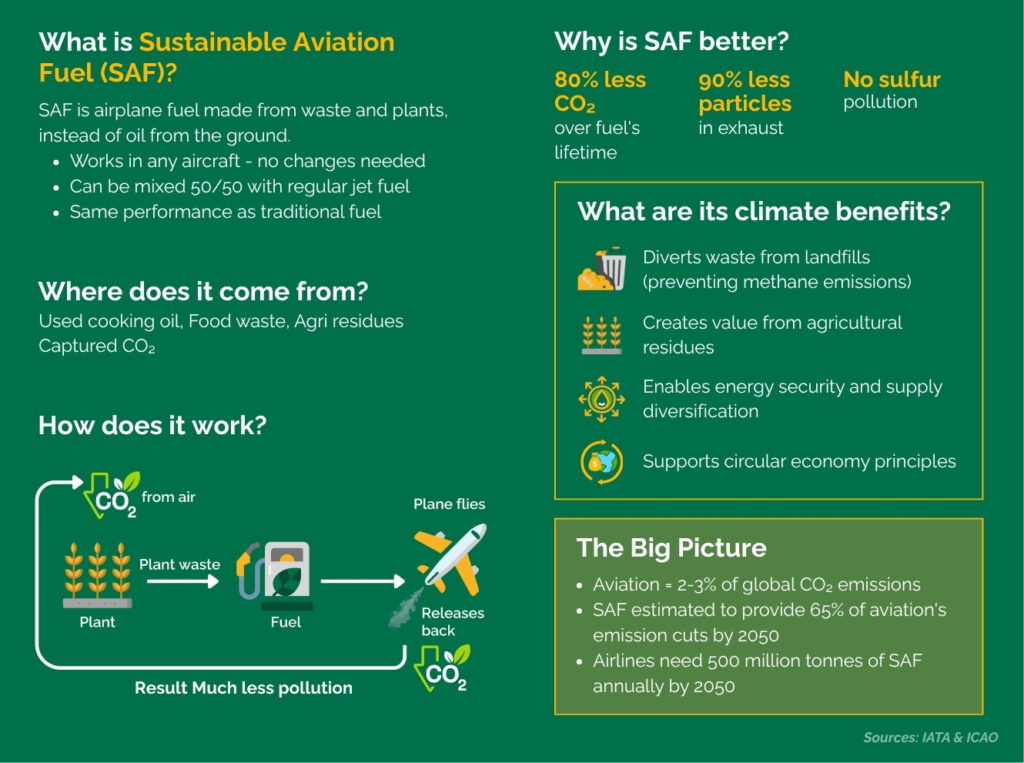

Breaking new ground with SAF

We have partnered with the Council of Scientific and Industrial Research – National Chemical Laboratory (CSIR-NCL) to develop a first-of-a-kind commercial-scale production of Sustainable Aviation Fuel (SAF) from ethanol —and potentially from methanol too.

This is based on NCL’s patented catalyst that enables a one-step oligomerization process – where small molecules are joined together to form larger molecules that closely resemble jet fuel.

While many have demonstrated the Ethanol-to-Jet Fuel process at lab scale, we hope to be the first to demonstrate it at an industrial scale.

Branded NG SAF (NCL-GPS SAF), this project combines NCL’s patented catalyst with our engineering expertise, and we hold the exclusive rights to commercialize it.

Why is this so significant?

Through NG SAF, we’re taking a truly home-grown approach—using ethanol from 2G agri-biomass as the primary feedstock.

So far, most commercial SAF has relied on the HEFA route (Hydroprocessed Esters and Fatty Acids), which utilises used cooking oil (UCO) or animal fat.

But, in India, large-scale HEFA production is not a feasible solution due to the lack of an organized UCO collection system and FSSAI restrictions on importing UCO

CSIR-NCL is a science and knowledge-based research, development, and consulting organization that is internationally known for its excellence in scientific research in chemistry and chemical engineering.

We are confident that with their scientific backing and our expertise in scaling cleantech solutions, we can deliver an indigenous and industrially viable SAF solution to the world.

Each of these objectives requires collaboration across functions. Let’s keep building, experimenting, and setting benchmarks for the industry together.

New R&D Lab in Bangalore

In October, we’ll be inaugurating our 12,000 sqft. R&D facility in Bengaluru’s Jigani industrial estate.

This state-of-the-art lab will bring together our Research and Development team from Pune and Bengaluru, and the extended engineering group under one roof.

We hope this new facility will help us strengthen our collaboration and speed up problem-solving.

This facility will serve as the hub for our next-generation biofuel and biogas technology development.

Watch this space for more updates from the lab!

Updates from the bioprocessing team

Patents filed:

- Membrane Based CH4 recovery system after VPSA/ PSA to improve recovery and purity of product gas – Final Patent filed.

- Single stage Thermophilic Anaerobic Digestion system for enhanced biogas production – Provisional patent filed.

PGTR process started at Barabanki

We achieved max yield at Barabanki and Jhajjar, in the range of 170-175kg CBG per ton of volatile solids (VS) added, which is 90% of the target number of 187kg CBG per ton of VS added.

Digitisation

We’ve taken steps towards digitisation, with automated compliance report generation, Labdesk Ver 02, Integration of Digester Health with Grafana.

Looking forward: What we hope to achieve in FY26

Developing new valorization pathways

for digestate, beyond FOM, to create products like silica, briquettes, or construction materials. This will help create new value streams for digestate, reduce waste and open new markets.

Advancing yield improvement

through faster digestion, feedstock flexibility, and new biological approaches.

Cost optimization

in CBG production through automation, process improvements, and import substitution.

Exploring future biofuel pathways

including green methanol and SAF, with focus on technical and economic viability — laying the foundation for our future portfolio.