Transforming CBG Plant Operations Through Digitisation

Sankalp Pathak

How LabDesk & ShiftKeeper Are Powering India’s Most Advanced Bioenergy Digital Ecosystem

Across India’s rapidly growing CBG (Compressed Biogas) sector, operational efficiency, process predictability, and real-time decision-making have become essential for scale. Traditional methods, such as handwritten logs, Excel-based laboratory records, and shift-by-shift manual reporting, no longer support the speed and accuracy required for modern plants.

GPS Renewables’ homegrown digital ecosystem marks a major shift, built by our bioprocess team at the Bengaluru HQ in collaboration with our in-house tech and software experts in the Climate Software Lab, Thiruvananthapuram.

At its core lies the seamless integration of two powerful systems: LabDesk, the engine for scientific data capture, and ShiftKeeper, the nerve center of plant operations. Together, they form the digital backbone that powers real-time analytics, dashboards, and compliance reporting across large-scale CBG installations.

Through digitisation of core workflows, we aim to improve data integrity, enhance decision-making, support early detection of digester instability, and enable multi-site benchmarking.

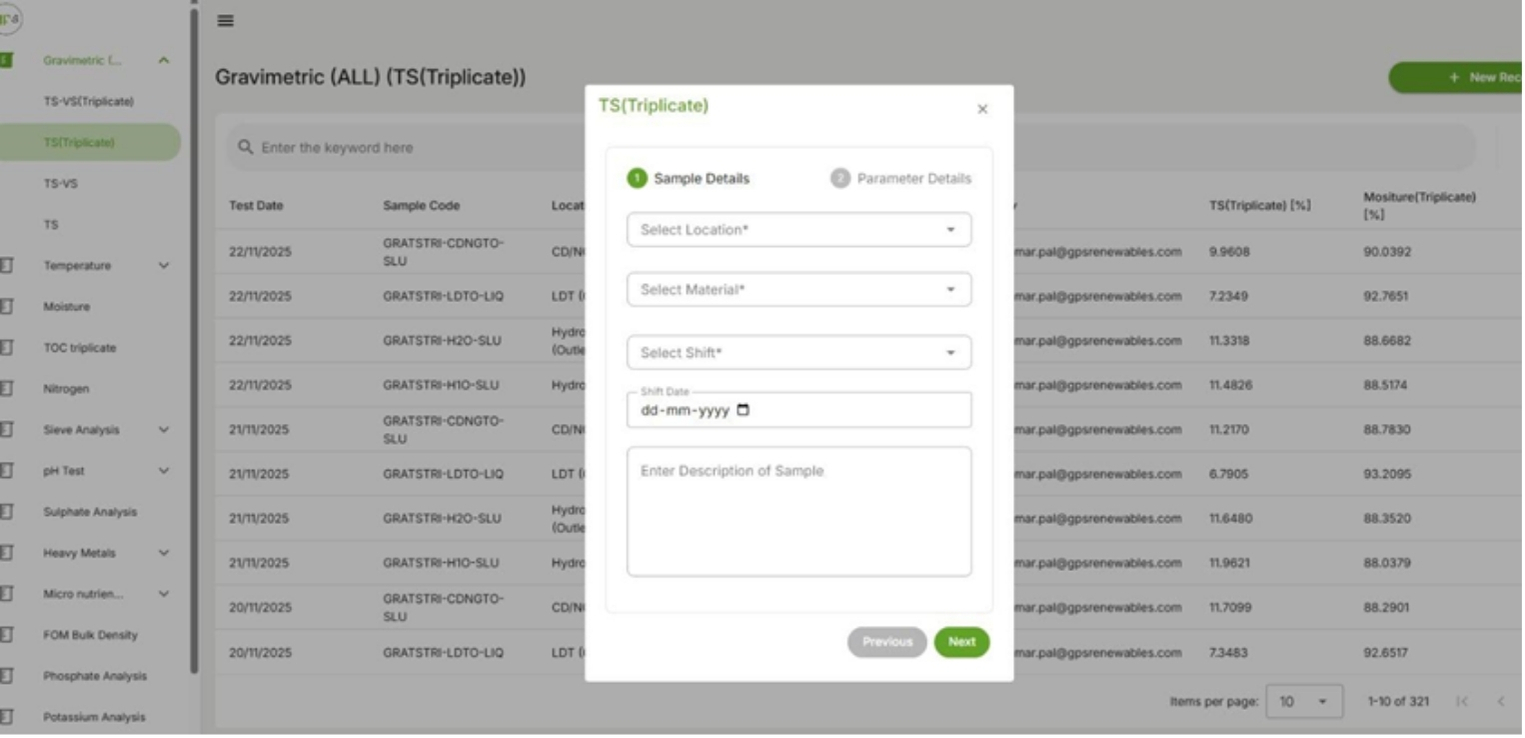

LabDesk: Precision Meets Standardisation

LabDesk digitises lab processes—TS/VS analysis, pH, sieve distribution, V/T ratio —via structured interfaces for accuracy and traceability. It auto-calculates all analysis values, cutting errors. In multi-feedstock plants, it flags TS, VFA and pH shifts – all of which signal microbial stress early, validating data for dashboard integration.

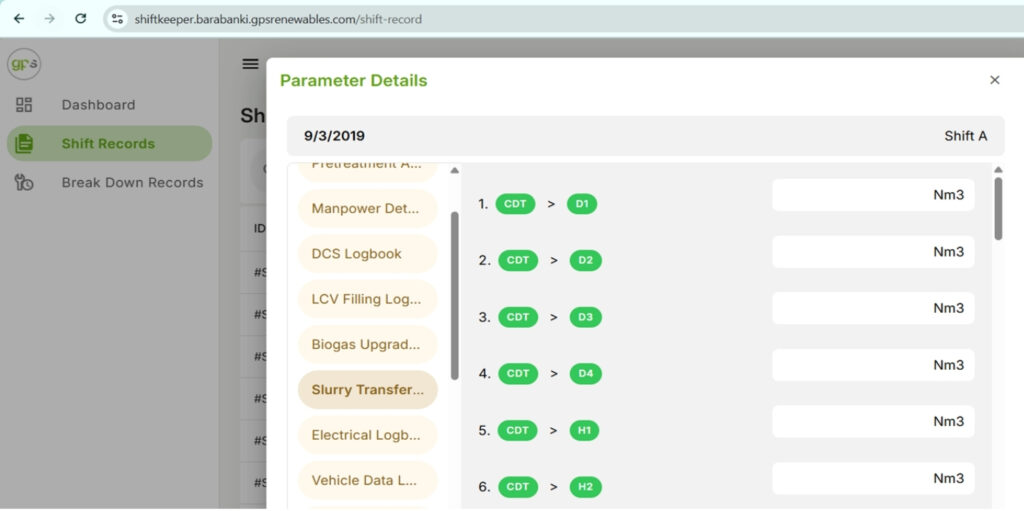

ShiftKeeper: The Digital Nerve Center of Operations

While LabDesk manages scientific accuracy, ShiftKeeper brings operational intelligence.

ShiftKeeper tracks substrate feeding, slurry transfers, digester in-out flows, biogas production, manpower, and FOM outputs—all timestamped and approved for accountability and visibility.

It shifts operations to predictive mode, flagging anomalies like backflows or excess transfers impacting TS, dilution, and mass & water balance.

The Unified Data Layer & Central Intelligence Engine

A central warehouse merges LabDesk/ShiftKeeper data, eliminating silos. This helps with consistent dashboards, MIS, and audits. It benchmarks methane yield, TS trends, flares, efficiency, and stability across sites.

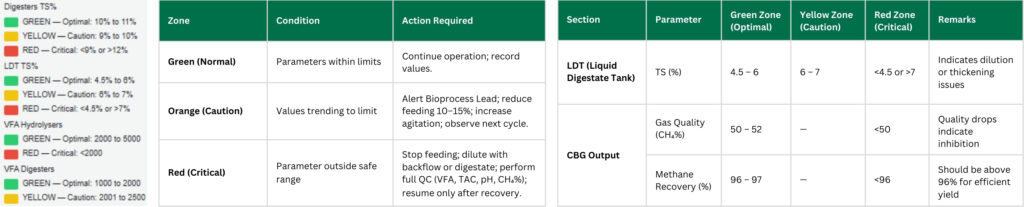

Color-coded zones (green: stable; yellow: warning; and red: critical) track digester health via built-in metrics: VS in – out, CBG purity, methane recovery, 5-day solids separation efficiency, 21-day trends of CBG yield.

Dashboards: Turning Data Into Decisions

Grafana dashboards monitor all the key operational and digester health parameters with color-coded tables and visualisations to highlight whether the plant is running within operational boundaries and warnings.

They enable fast decisions for maximum uptime, stable production, and fewer upsets.

Impact Across CBG Plants

.

The adoption of LabDesk and ShiftKeeper has created a new standard for digital biogas operations. Plants using this ecosystem have reported major operational improvements, including:

Overall improvement in data accuracy and validation completeness

Early-warning detection of digesters approaching instability

Fully automated daily/weekly/monthly MIS reporting

Faster troubleshooting through real-time traceability

This robust digital foundation — built by our Bengaluru bioprocess team and the Climate Software Lab in Thiruvananthapuram — sets a new benchmark for scalable, technology-driven CBG operations, empowering GPS Renewables to lead India’s bioenergy transformation.